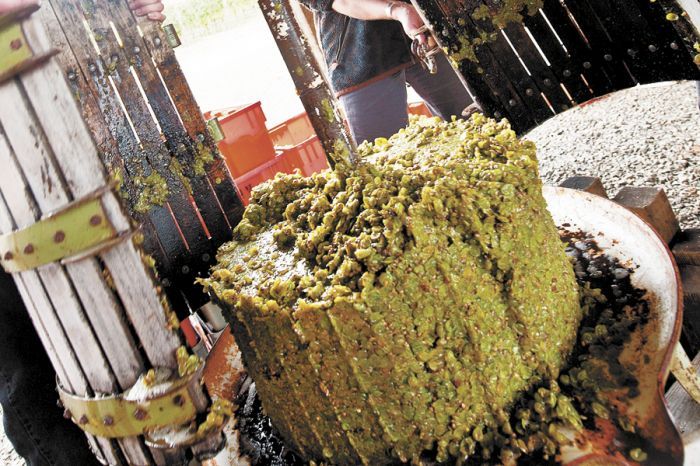

Pomace-ing Start

By Daniel Robison

Researchers at Oregon State University in Corvallis have discovered how to turn pulp from crushed wine grapes into a natural food preservative, biodegradable packaging material and a nutritional enhancement for baked goods.

The U.S. wine industry creates a tremendous amount of waste from processing more than 4 million tons of grapes each year, according to the U.S. Department of Agriculture. Wineries typically pay for the pulp to be hauled away, but a small percentage is used in low-value products such as fertilizer and cow feed.

“We now know pomace can be a sustainable source of material for a wide range of goods,” says researcher Yanyun Zhao, a professor and value-added food products specialist with the OSU Extension Service. “We foresee wineries selling their pomace rather than paying others to dispose of it. One industry’s trash can become another industry’s treasure.”

The pulp, consisting of stems, skins and seeds, is known as pomace and is packed with dietary fiber and phenolics, which have antioxidant effects. OSU researchers have dried and ground it to create edible and non-edible products.

For example, they extracted dietary fiber from pomace and turned it into powders that can be added to foods. Because the phenolics in pomace also control microbial growth and prevent fats from deteriorating, OSU researchers also added the powdery fiber to yogurts and salad dressings to extend their shelf life by up to a week without changing taste or texture.

The researchers also used pomace to make colorful, edible coatings and films that can be stretched over fruits, vegetables and other food products. They contain antioxidants, seal in moisture and control the growth of some bacteria.

Additionally, the scientists added pomace powders, which are gluten-free, to muffins and brownies. They replaced up to 15 percent of the flour in the recipes with it, increasing the fiber and antioxidants in the baked goods. The research continues as scientists are also adding pomace to yeast breads.

“Adding fiber-rich ingredients can change dough’s absorption qualities and stiffness,” says OSU cereal chemist Andrew Ross. “We’re trying to find the right balance of pomace in dough while measuring the bread for its density, volume, color and taste. Commercial bakeries need this information before using pomace flour for large-scale production.”

OSU has also made pomace into biodegradable boards, which can further be molded into containers, serving trays and flowerpots. After burial in soil for 30 days, the products degraded by 50 percent to 80 percent.

Researchers found the methods for making products from pomace vary depending on whether the pulp came from red or white grapes; that’s because winemaking processes differ for each varietal producing pulp with varying levels of sugar, nitrogen, phenolics and other compounds. In their experiments, researchers used pomace from grapes that included Pinot Noir, Merlot, Morio Muscat and Müller-Thurgau.

Currently, OSU is seeking to establish partnerships with companies interested in marketing the products it has developed. The research has been published in various journals, including the Journal of Applied Polymer Science, Food Chemistry and Journal of Food Science.

Story courtesy of OSU Extension Service.